- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

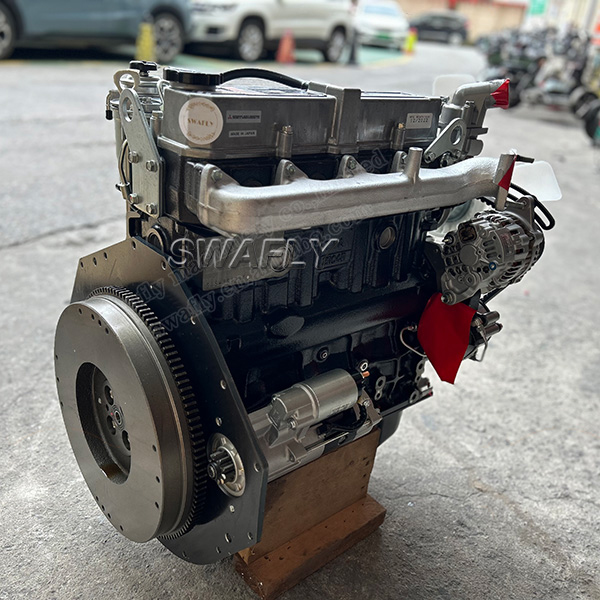

Mitsubishi Heavy Industries: Leading the Tier 3 Era with Purpose-Built Forklift Engines

2025-05-20

Since April 1, 2016, China’s non-road machinery has fully entered the National III (Tier 3) emissions era. As a world-renowned manufacturer of non-road engines, Mitsubishi introduced its mechanical Tier 3 emission engines specifically designed for forklifts to the Chinese market as early as 2008. These engines have been widely adopted by leading domestic forklift manufacturers. Additionally, Mitsubishi’s EPA Tier 4-compliant forklift engines (EPAT4) are already being supplied in bulk to the North American market.

Unlike most engine manufacturers, Mitsubishi is both a forklift producer and an engine manufacturer, ensuring that its engines are purpose-built for forklift applications. Key advantages include:

· Optimized for forklift conditions: Designed specifically for the demands of forklift operation.

· Swirl combustion chamber: Delivers superior cold-start performance, reduced vibration, and lower noise levels.

· Long-stroke design: Provides enhanced low-speed torque—ideal for forklift workloads.

To meet the needs of the Chinese market, Mitsubishi leverages its strong R&D capabilities to introduce the SQ and SS series of mechanical Tier 3 engines, covering 1.5–7 ton forklifts. Among these:

· The S4S engine (2.5–3.5 tons) has surpassed 300,000 units in cumulative sales, proving its reliability over time.

· The S6S(T) (4.5–7 tons) employs a rare 6-cylinder technology, offering smoother operation and greater durability.

· For 8+ ton forklifts, MHI utilizes mature electronically controlled high-pressure common rail technology to meet Tier 3 standards.

· Mitsubishi Heavy Industries remains committed to energy efficiency and emission reduction, upholding its "customer-first" philosophy. By developing environmentally friendly technologies and products, MHI strives to contribute to a sustainable society.