- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

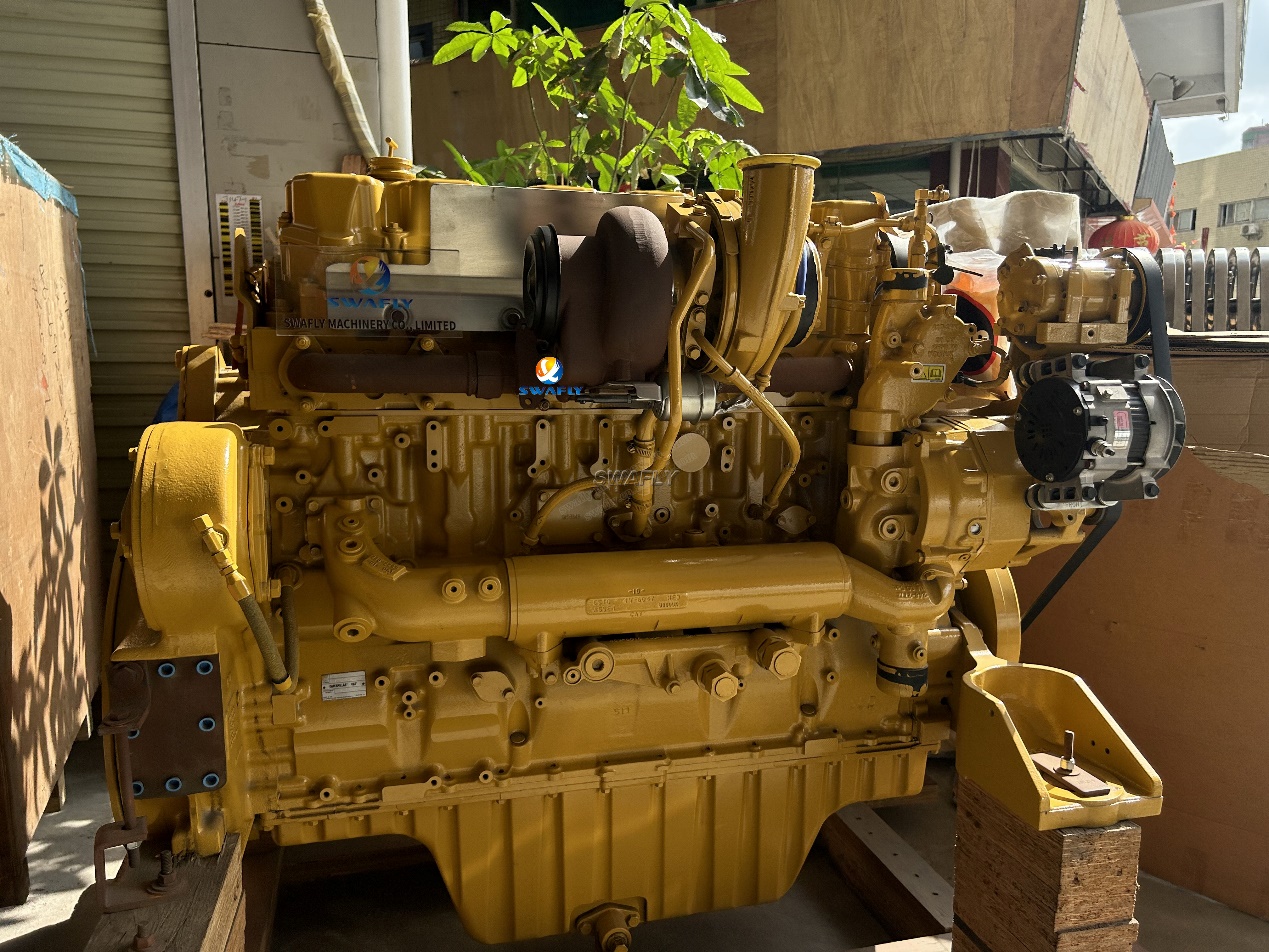

Caterpillar CAT Loader C15 Engine: Maintenance and Troubleshooting

2025-04-15

The Caterpillar C15 engine delivers robust performance with 550 horsepower and 1,850 Nm of torque, meeting stringent global emission standards. Its turbocharging and direct injection technologies ensure high fuel efficiency, while high-strength castings and modular design make it suitable for agricultural machinery, mining equipment, and construction vehicles—maintaining stable output even under extreme conditions. The intelligent sensor system enables quick fault code diagnostics, reducing maintenance costs by over 30%.

The Caterpillar Loader C15 engine is a high-performance, low-emission diesel engine produced by Caterpillar Inc., widely used in heavy-duty machinery such as loaders, excavators, bulldozers, and generator sets. Renowned for its exceptional reliability and power, this engine has earned global acclaim. This article provides a detailed overview of the C15 engine’s technical specifications, performance features, applications, and maintenance & troubleshooting guidelines.

1. Technical Specifications

The C15 engine is a 15.2L diesel engine with a 137mm bore and 171mm stroke. It delivers 404–550 HP (depending on configuration) and a maximum torque of 1,850 Nm. The engine has a dry weight of 69,870 kg, featuring an inline 6-cylinder, 4-stroke design with a compression ratio of 17.0:1. Its turbocharged aftercooled (TA) intake system and direct fuel injection ensure optimal combustion, while the rotation direction (viewed from the flywheel end) is counterclockwise.

Key performance metrics:

- Rated power: 306.5 kW @ rpm

- Power range (1800–2100 rpm): 354–433 kW (475–580 bhp)

These specifications enable the C15 to deliver stable, high-power performance in heavy-duty applications.

2. Performance Features

1.High Efficiency

oAdvanced combustion and turbocharging technologies maximize power output while improving fuel economy.

oOptimized engine structure, precision fuel injection, and reduced friction enhance fuel efficiency, lowering operational costs and environmental impact.

2.Low Emissions

oComplies with EPA Tier 4 Final (U.S.), EU Stage IV, and proposed Stage V non-road emission standards.

oEquipped with Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR) systems to minimize pollutants.

3.Exceptional Reliability

oHigh-strength materials (cast iron block/head, forged steel crankshaft) ensure durability.

oPrecision machining and heat treatment enhance resistance to wear and extreme conditions.

4.Easy Maintenance

oModular design simplifies component replacement (fuel system, cooling system, sensors, etc.).

oHigh-quality filters, seals, and bearings extend service life and reduce downtime.

3. Applications

The C15 engine powers a wide range of heavy machinery:

1.Agriculture – Tractors, combine harvesters

2.Construction – Cranes, loaders, road rollers

3.Mining – Crushers, drills, haul trucks

4.Other Uses – Airport ground support, hydraulic power units, irrigation systems

Its versatility and robustness make it a preferred choice for demanding industrial applications.

4. Maintenance & Troubleshooting

Preventive Maintenance

- Regularly inspect seals, gaskets, and hoses to prevent leaks.

- Clean air intake/exhaust systems and adjust valve clearance.

- Use recommended engine oil and coolant to prevent overheating and oil/coolant mixing.

Common Fault Codes & Solutions

- P0001 – Fuel pressure sensor circuit issue

- U0400 – Communication system error

- Throttle signal abnormalities – Check pedal sensor/wiring

- Overheating – Inspect cooling system (radiator, water pump)

Troubleshooting Tips

- Excessive intake restriction? Replace/clean air filters.

- Turbocharger failure? Inspect for damage or blockage.

- Oil/coolant mixing? Verify head gasket and cooling system integrity.

5. Conclusion

The Caterpillar C15 engine stands out for its power, efficiency, and reliability, serving critical roles in agriculture, construction, and mining. With proper maintenance, it ensures long-term performance in harsh environments.

As Caterpillar continues to innovate, users can expect even more advanced and sustainable engine solutions. Understanding the C15’s specs, maintenance needs, and troubleshooting methods will help operators maximize its lifespan and productivity.

(Note: For precise diagnostics, always refer to the official Caterpillar service manual or consult certified technicians.)